Do You Have A Manufacturing Project We Can Help With?

Complex, Commercially Viable Part-Making

5-axis machining at IMG

The 5-axis machines we use at IMG welcome medium and large parts, and the work is completed faster and with higher quality thanks to simultaneous 5-axis milling and turning capability. If you have a complex part that you want to machine, talk to IMG. You’ll get open, clear and long-term manufacturing plans that meet stringent tolerances and commercial targets.

High Throughput, Remarkable Accuracy

High speed vertical FANUC robodrills

It’s easy to put a design on paper, but it can be tough (and costly) to turn it into a real-world part. Thankfully, the staff at IMG offers designing-for-manufacture insight that reduces the overall cost. And with ultra high speed robodrills—24,000 RPM spindle speeds and 2,800 IPM travel rates—our quick work lowers that cost even more.

Any Item, Any Shape, Any Configuration

Milling and turning equipment at IMG

Our comprehensive roster of milling and turning equipment (featuring rotary tables and plenty of 5-axis capability) means we can manufacture any part you want us to make. IMG maintains full manufacturing support from prototype through production, and digital photographs of every important setup ensure identical production for every run.

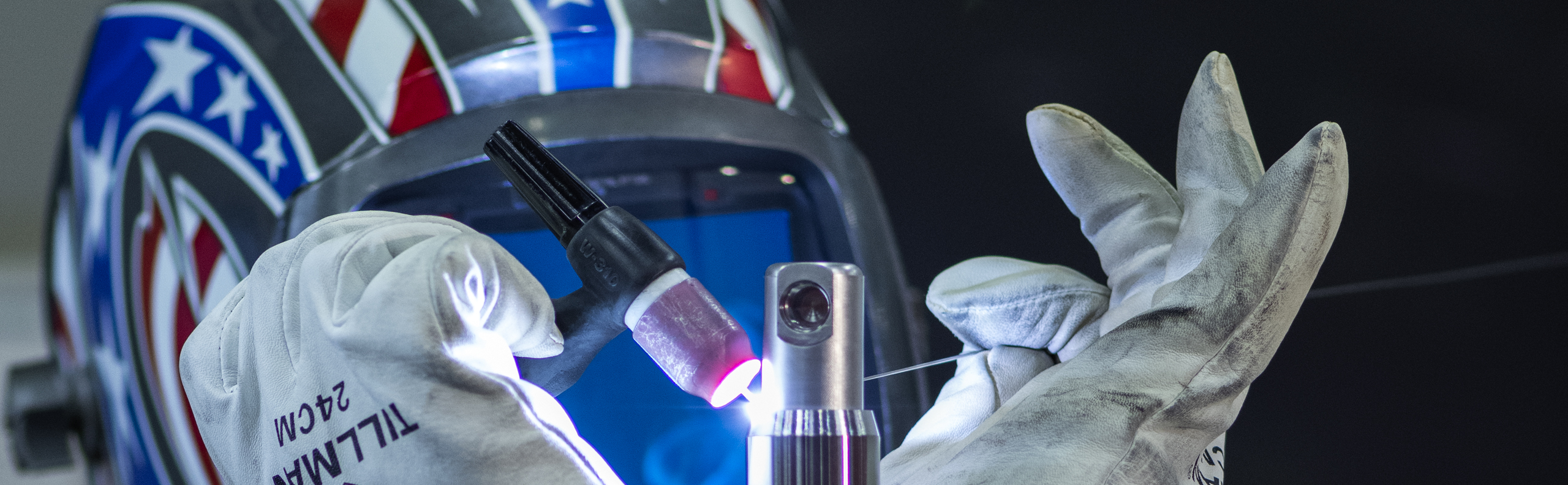

A Better Welding Process

TIG/MIG welding at IMG

With state-of-the-art equipment, journeyman welders and the support of a world-class machine shop, our tungsten inert gas (TIG) and metal inert gas (MIG) welding expertise shines through in every job.

World-Leading E-Beam Welding

Electron beam welding at IMG

Combined with our partners at Applied Fusion, we have perfected the art of electron beam welding. If your part requires it, you won’t find a better option on the planet.

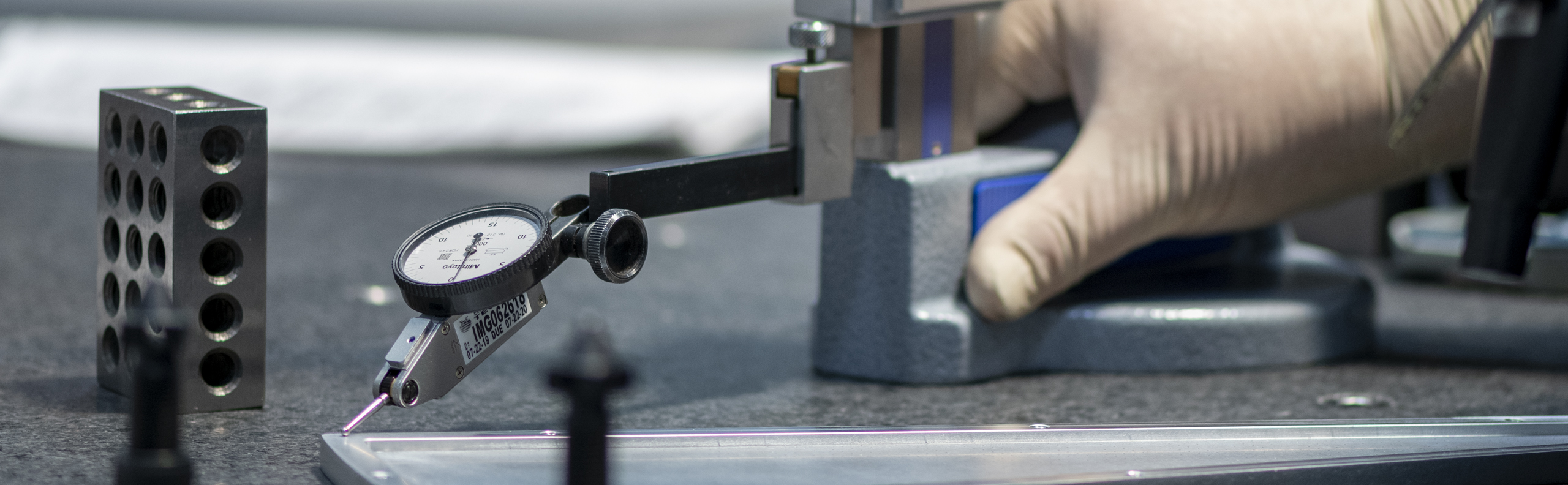

Attention to Detail

Assembly and testing at IMG

With a comprehensive range of in-house equipment, you’d have a hard time finding a partner that handles QC better than we do at IMG. Our assembly area runs two shifts, seven days a week, and our assembly and testing equipment is ideal for the semiconductor, aerospace and defense industries.

Where Experience Meets Resources

Quality and reliability at IMG

Thanks to continuous investment in both employee training and the latest technology, quality assurance processes at IMG are unparalleled. Our operations are AS9100 D and ISO 9001:2015 certified with the highest customer satisfaction index rating, and we match the quality of our human resources with the best metrology and inspection equipment on the market.

Precision Engineering and Manufacturing Services

We look for two things when choosing projects: collaboration and complexity. No matter how challenging the project, the versatility of our equipment and the steadfast support of our people lets us get the job done the right way the first time.

Collaborative Engineering

Our established process capabilities shape our selection of material, critical value-added external processes, manufacturing methodologies and resource planning. Collaboration with our customers makes a first-time pass on new builds a regular occurrence—with repeatability and cost reduction to boot. Our knowledge in metallurgical, mechanical and precision engineering turns creative and challenging designs into commercially viable manufactured parts.

Complex Manufacturing

Simply put, we thrive on complexity. Working on quick-turn new builds or production parts was one of the best parts of the job when we opened our doors, and it still is today. During 40 years in the San Francisco Bay Area, we’ve transformed rapidly to meet the demands of emerging technologies. The Silicon Valley effect has been a huge influence on us. We don’t fear change; we welcome it, because it’s made us into a best-in-breed complex manufacturing business.

Versatile Manufacturing Systems

The full rotary tables and 5-axis capabilities at IMG create any item in any shape and configuration. Nearly 50 milling centers welcome just about anything, from small parts to parts that are up to 118″ by 90″. Our two vertical turning centers and ten CNC lathes manufacture parts as large as 93.5″ in diameter.

Comprehensive Support

We provide full manufacturing support from prototype through production. Digital images of every important set-up guarantee identical production every time. In recent years, we have expanded our capabilities to support our customers’ unique design, engineering and production needs. We remain highly responsive to the customers we serve. Without them, we don’t exist.